With over 40 years of experience in the industry, we offer the broadest range of in-line flexo, screen, and flexo-screen combination printing choices to meet all your labeling needs. Our pressure sensitive labels are solutions suitable for a wide range of applications and industries, including food & beverage, health & beauty care, home & garden, agro-chemical, and automotive products.

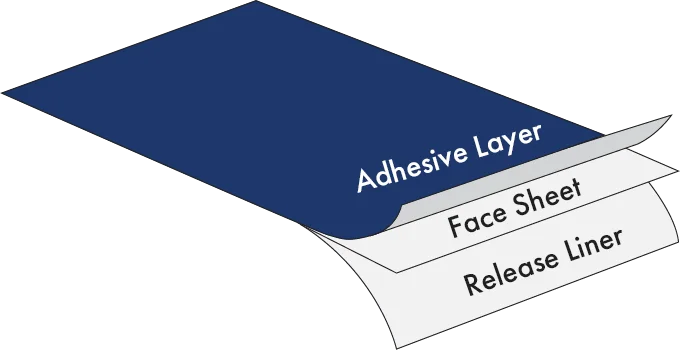

A Pressure Sensitive Label (PS Label) is a versatile, self-adhesive labeling solution. Labels are die cut into any shape or size, usually delivered on a roll and composed of three basic components:

Face Sheet

Adhesive Layer

Release Liner

This is the label’s surface, where we print your graphics, text, and branding elements. The face sheet material is available in either paper or film, each offering a wide range of standard and custom finishes.

Positioned beneath the face sheet, the adhesive layer attaches the label to your container. Adhesives are formulated to suit specific surfaces and conditions.

This backing material protects the adhesive until the label is ready to be applied. During application, the release liner is removed, allowing the label to be applied onto the container with ease. Release liners are available as PET or paper.

The label application process for pressure sensitive labels is incredibly straightforward. While most of our customers utilize machine application, they can also be applied by hand. The release liner is simply removed, allowing the label to adhere securely to the desired surface.

Pressure sensitive labels come in a variety of material options to suit any use environment or labeling requirement.

Paper Face Sheet

Frequently the preferred option for cost-effective high-volume printing, paper labels are also offered in luxurious textures and vibrant colors.

Film Face Sheet

A film face sheet provides superior durability and is chemical and water resistant. Film labels are available in clear, white, metalized, and specialty finishes. These labels are ideal for products that require a high-end look or need to withstand harsh conditions.

Adhesives

Adhesive qualities are formulated to suit specific applications and container surfaces. Adhesives range from permanent to removable and repositionable. Additionally, adhesives are tailored for use, storage and application temperature ranges.

Liners

We produce high-quality easy-to-apply pressure sensitive labels on either paper or PET liners. Liner selection is often driven by your application equipment or company preference.

Sustainable Options

All three layers of a pressure sensitive label have recycled or sustainable options including FSC-certified or recycled face sheets, compostable or PET recyclable adhesives, and silicone-free or recycled liners.

Based on your product’s needs, our label specialists guide you in choosing the best label materials for your project. During our discovery meeting we will discuss factors such as container type, application requirements, use environment, aesthetic goals, sustainable options and cost. Together we will find the best face sheet, adhesive and liner combination for your project.

Our 12 color, 100% inline manufacturing process allows for cost-effective additions of specialty inks, coatings and lamination. Custom design options for pressure sensitive labels are virtually endless.

The vibrancy of our UV inks can be enhanced by the addition of screen inks or specialty inks such as metalure and pearlescent. Some of our most popular options can be found in our specialty printing techniques.

Self-adhesive labels are finished and protected with either varnish or a laminate. Standard offerings are gloss, matte, satin and textured. Finishing options to differentiate your label include patterned, holographic, and cast and cure coatings and laminates, which can come in a variety of finishes and patterns.

UV inks are waterproof and chemical resistant. Our inks will stand up to some of the harshest use and application environments

These specialized features, Q-Clear and the No Label Look, provide innovative solutions to elevate your product packaging, ensuring it captures consumer attention and reinforces your brand’s premium quality.

Q-Clear is our proprietary solution designed to create stunning 3-D effects on clear containers, providing a unique visual impact that enhances brand recognition. This innovative feature offers:

Achieve the sleek, seamless appearance of direct screen printing on your bottles without the associated risks and costs. The No Label Look offers:

Promotional pressure sensitive labels can be a powerful tool for marketing and branding efforts. They can be used to attract consumers, boost sales, and build brand loyalty. Marketers often select:

Pressure sensitive labels (PS labels) are suitable for a wide range of product label applications and industries. Their adaptability and customization make them an ideal choice for premium packaging. Common industries we serve are:

Tailored for products such as fertilizers, pesticides, and herbicides, these labels are built to endure exposure to sunlight, moisture, and chemicals.

Ideal for labeling bottles, cans, jars, and packaging, providing essential information such as ingredients, nutritional facts, and branding.

Perfect for high-end cosmetic and skincare products, offering options like the No Label Look for a sleek, premium appearance.

Labels that resist water, chemicals, and wear, ensuring they remain intact and legible on products like detergents and disinfectants.

Designed to relay pertinent information while keeping an aesthetically appealing design, these labels are for products like paints, industrial coatings, and other products bought at hardware stores.

Are you ready to begin the label project with QAL? Share your ideas with our dedicated customer service team and learn more about how we can supply high-quality label solutions for your products.